Aerospace

Aerospace

Aerospace belongs to explorers. We have been instrumental in pioneering the establishment of optimization centers at major aerospace OEMs. Our simulation technologies develop complex, high-fidelity finite-element models for the predictive virtual testing of airframes, engines, and aircraft interiors. We accurately simulate impact damage and correlate against vulnerability events. Now, new methods fuse with old for entirely new processes that take us further than ever into the beyond.

Design for the Future

For years the predominant pre-processor and solver for aircraft structural analysis were technologies with roots dating back to the Apollo program. During the past decade, the increased adoption of topology optimization in the aerospace industry created a shift. Now, modern solution-specific workflows are changing the user experience for pre-processing and bringing increased efficiency to the certification by analysis process.

Increase Engineering Agility

Aerospace organizations are seeking to empower design engineers not only to design, but to analyze, and certify parts to reduce development times with simulation. This is motivating the development of a new type of tool, which provides an environment for analysis, optimization, manufacturing checks, and geometry editing; supporting fast design iterations and decision making.

Streamline Concept Decision Making

Increased adoption of data analytics will shape the way early program decisions are made. Applying statistical methods, such as dimensionality reduction to a large number of design variables, will help identify a subset of critical performance criteria. The essential measures can then be considered during early studies, using advanced physics simulations to identify the most promising design concepts.

Moving to Certification by Analysis

Modern tools: Aircraft manufacturers and suppliers are striving to speed up the aircraft certification process, which is primarily based on physical tests. Many efforts for achieving certification by analysis have been constrained by legacy analysis tools and processes. The intuitive user experience and integrated solution workflows of Altair HyperMesh™ are bringing increased efficiency to the certification by analysis processes across the industry. Simulation-driven design tools, including Altair OptiStruct™ topology optimization, are growing in adoption.

Analysis Report Automation: Creating detailed stress reports can be time consuming and repetitive, taking up valuable engineering time better spent interpreting and understanding simulation results. Process automation can decrease report generation and update time by up to 80 percent. Altair Automated Reporting Director™ ensures all reports are assembled with a standard structure and format for the model description, model verification, and results presentation.

Optimization and Minimum Weight Designs: To reduce product development time, organizations need to use simulation and optimization to drive designs rather than validate them. To achieve this, we empower engineers to apply simulation and optimization up-front in the design cycle with tools such as Altair Inspire™ and Altair SimSolid™. These tools support the analysis, optimization, manufacturing checks, and geometry editing functions required to power fast design iterations and decision making early.

Advanced Simulation and Analysis

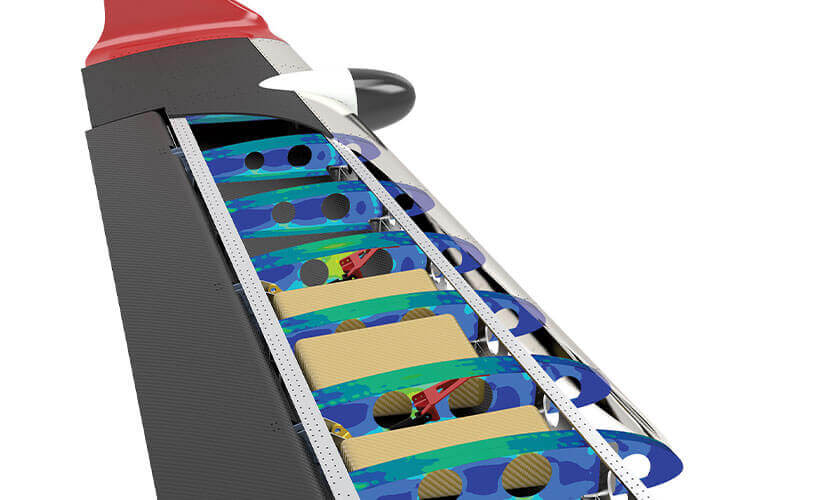

Composite Design: OptiStruct® is widely used for the design and optimization of laminate composites. It delivers optimal ply shapes, the optimal number of plies, and the optimal stacking sequence, while observing manufacturing constraints. Altair Multiscale Designer™ provides accurate and efficient simulation of materials and parts manufactured with continuous and chopped fibers, honeycomb cores, lattice structures, and more.

Mechanism Simulation: Altair MotionSolve™ provides a multibody integrated solution to analyze and improve mechanical system performance. MotionSolve® simulates dynamic systems including ground aircraft operation (taxi, takeoff, landing, braking, and rejected take-off), landing gear retraction and evaluation of gear forces, flap mechanism, flight control and dynamics, door opening mechanisms, helicopter design, satellite control, and packaging study of seats.

Propulsion Development: OptiStruct supports rotor dynamics solutions including rotor effect, mode tracking, and rotor energy from complex eigenvalue analysis. In addition, it provides comprehensive physics for nonlinear analysis and durability, including solutions for heat transfer, bolt and gasket modeling, hyperelastic materials, and efficient contacts. Altair also provides simulation to support electric propulsion design decisions regarding the thermal, mechanical, and electromagnetic performance. Full system efficiency can be optimized with power electronics and control modeled in Altair Activate™.

Understanding System Interactions

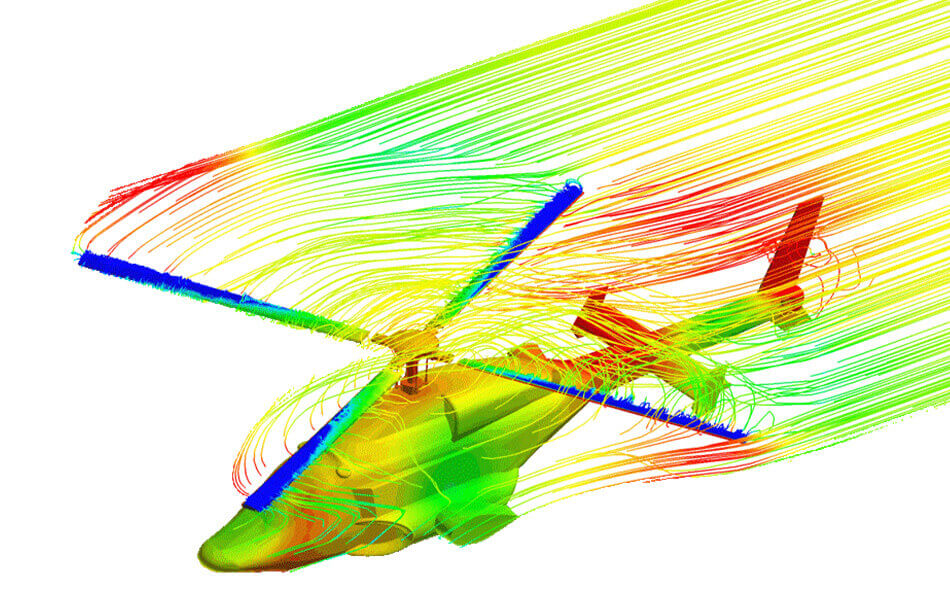

Multiphysics Simulation: Altair provides multiphysics-enabled software to enable a wide range of interacting physical models to fully describe a system’s mechanical, electromagnetic, and aerodynamic performance. For example, the air pressure field during flight on a radome can be simulated with Altair AcuSolve™, a computational fluid dynamics (CFD) solver. The pressures can then be mapped onto an OptiStruct model to accurately predict the structural response of the radome under aerodynamic load.

Antenna Design and Placement: More airborne radio equipment is being installed on aircraft. Typically, an aircraft is equipped with dozens of systems – weather radars, communication and navigation systems, surveillance, and air traffic control equipment – requiring multiple and different antennas types working at different frequency bands. The performance of an antenna is influenced by the structure it is mounted on. Altair Feko™ enables optimization of antenna design and placement for system integration.

Electromagnetic Compatibility: Electromagnetic compatibility (EMC) ensures the safe operation of an aircraft by verifying conformance with EMC immunity and emission standards. Feko® can simulate important EMC criteria including antenna coupling to ensure radio system performance and sensitivity to high-power radio signals from external systems called high-intensity radiated fields (HIRF). Simulation guides design decision to mitigate HIRF effects that can induce electromagnetic fields around equipment or high frequency currents on cables leading to a degradation of equipment performance.